Precision fermentation

Description of the innovative solution

Protein production in conventional animal farming systems has a very high environmental footprint and requires extensive land use. Cell cultures, especially those of yeast, have been genetically engineered to produce desired specific proteins. The yeast is grown in fermentation tanks with a productivity many-fold higher than in animal based systems. Input for growth of the yeast can be waste streams, sugar or other plant based material. Examples of precision fermentation are vanillin and enzyme of rennet, which turns milk into curds for cheese. Approved in the U.S. in 1990, rennet is now...

Protein production in conventional animal farming systems has a very high environmental footprint and requires extensive land use. Cell cultures, especially those of yeast, have been genetically engineered to produce desired specific proteins. The yeast is grown in fermentation tanks with a productivity many-fold higher than in animal based systems. Input for growth of the yeast can be waste streams, sugar or other plant based material. Examples of precision fermentation are vanillin and enzyme of rennet, which turns milk into curds for cheese. Approved in the U.S. in 1990, rennet is now widely used in cheese making. This innovation makes it possible to produce almost any complex organic molecule. These include the production of proteins (including enzymes and hormones), fats (including oils), and vitamins to precise specifications, abundantly, and ultimately at marginal costs approaching the cost of sugar.

Examples and additional resources

Real-world examples

See this solution in action in different contexts and settings around the world

Precision Fermentation Company

Additional resources

Learn more about this solution through studies, articles, business cases, and other information

Precision fermentation and cellular agriculture

Contacts

Connect to others working on and with this solution around the world

Pathways to uptake

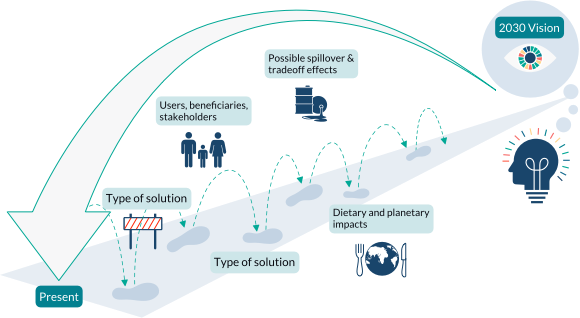

Engage with our “backcasting tool” to imagine and design “pathways to uptake” for this solution in your setting.

This process involves defining a future vision of this solution being used in your context, and then working “backwards” to identify necessary steps to achieve this vision by 2030. Going through this exercise as an individual or with a team can help to clarify the WHAT/WHEN/HOW of moving a solution (or package of solutions) towards having major impact. We hope these pathways will inspire outside-of-the-box thinking, creative approaches, and actionable concrete steps to move ideas into action.

Pathway builder

Explore pathways for this solution

Be the first one and add a pathway for this solution!