Edible films and coating

Description of the innovative solution

The consumption of and demand for a wide variety of fresh produce with a long shelf life has risen over the last few decades. However, once fruits and vegetables are harvested, they rapidly undergo biological and physiological changes that diminish their texture, taste, and color. Around 30 to 40% of total fruits and vegetables are lost between harvest and final consumption. Once picked, crops release ethylene, which quickly ripens the goods, and they transpire, resulting in water loss, which softens produce. Producers struggle to maintain the quality of minimally processed food for a long...

The consumption of and demand for a wide variety of fresh produce with a long shelf life has risen over the last few decades. However, once fruits and vegetables are harvested, they rapidly undergo biological and physiological changes that diminish their texture, taste, and color. Around 30 to 40% of total fruits and vegetables are lost between harvest and final consumption. Once picked, crops release ethylene, which quickly ripens the goods, and they transpire, resulting in water loss, which softens produce. Producers struggle to maintain the quality of minimally processed food for a long period of time, decreasing the amount of viable products they can sell in markets. A way to counteract the discrepancies between demand for produce and its short shelf life, edible films and coatings preserve uncut fruits and vegetables for a longer period of time than untreated produce. These innovations shield produce from water loss, pathogens, and color changes by creating a barrier between the food and its environment. By retaining moisture and slowing color changes and ripening, edible coatings and films can preserve the nutritional quality of fruits and vegetables. A variety of coatings derived from natural sources have been used for a host of fruits and vegetables around the world. Alginate, a compound found in the cell walls of brown algae, has been used for coating sliced apples; xanthan gum often preserves baby carrots, and beeswax and carnauba wax are also common films for fruits and vegetables. People have used edible coatings to preserve the taste, texture, and color of produce since at least the 12th century, and the U.S. approved its first edible coating patent in 1916. They have been widely used on pre-cut fruits and vegetables.

Examples and additional resources

Real-world examples

See this solution in action in different contexts and settings around the world

Additional resources

Learn more about this solution through studies, articles, business cases, and other information

A study on the development of edible films and coatings with antimicrobial factors that inhibit the growth of microbes on fruits and vegetables, an food safety and preservation innovation.

Review of edible Coating of Fruits and Vegetables

Shelf Life Extension of Toasted Groundnuts through Soy Protein-Based Edible Coating

Contacts

Connect to others working on and with this solution around the world

Pathways to uptake

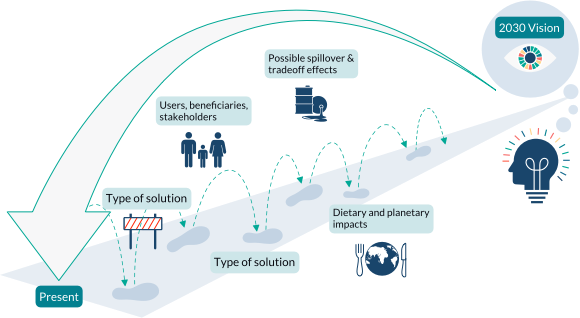

Engage with our “backcasting tool” to imagine and design “pathways to uptake” for this solution in your setting.

This process involves defining a future vision of this solution being used in your context, and then working “backwards” to identify necessary steps to achieve this vision by 2030. Going through this exercise as an individual or with a team can help to clarify the WHAT/WHEN/HOW of moving a solution (or package of solutions) towards having major impact. We hope these pathways will inspire outside-of-the-box thinking, creative approaches, and actionable concrete steps to move ideas into action.

Pathway builder

Explore pathways for this solution

Be the first one and add a pathway for this solution!